Project Design and Planning

Crafting Concept into Reality with Commercial Louvres and Screens

Crafting Concept into Reality with Commercial Louvres and Screens

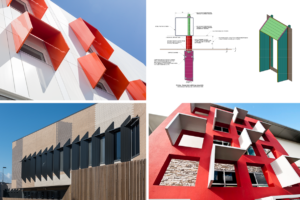

At design stage, we collaborate with specifiers, architects, engineers and builders to transform an idea into a practical solution.

We achieve this through sketches, technical drawings, 3D modelling, prototypes, and initial cost estimates.

From the start, Louvreclad works tirelessly to turn a concept into reality in the best way possible. We focus on the initial project design detail, sharing our industry and product knowledge, and setting realistic expectations from the outset.

Louvreclad has been providing exceptional exterior louvre and sunscreen building solutions for three generations. We understand that every project is different and enjoy the challenge of extraordinary designs.

Our business is built on the ability to grasp different needs and objectives and transform them through our louvre and screening products to deliver remarkable façade solutions that combine superior form and function.

Operational Flowchart

Stage 1 – Define & Discover

Louvreclad specialises in providing turnkey solutions for large scale projects. At design stage, we work alongside specifiers, architects and engineers to transform conceptual ideas into practical solutions. This is achieved through good collaboration and communication through sketches, technical drawings, 3D modelling, prototypes and meticulous end-to-end project planning.

- Early design involvement

- Design development & engineering support

- Product samples & custom prototypes provided for bespoke designs

Stage 2 – Estimating & Tender Submission

To ensure we provide and accurate proposal we would like to gain a good understanding of your project. Our sales and estimating team have the experience and expertise to understand the key design requirements for a successful project and can offer design advice or provide value engineering options if need be.

Further to this, we would be happy to meet with you via Zoom or Teams to discuss your project requirements.

-

- Site meetings

- Analyse scope and complete takeoffs

- Budget costing and proposal

- Alternative improvements offered to the scope of works

- email tender documents to: sales@louvreclad.com

Stage 3 – Proposal & Engagement

Louvreclad provides comprehensive proposals that take into account the best and most economic solutions for the project. Our detailed project proposals carefully outline the scope of works, lead times and warranties associated with the project. With the design, engineering and manufacturing processes managed in-house, we can easily provide a realistic preliminary delivery schedule.

-

- Contract agreement

- Final scope of works

- Confirm commencement dates

Stage 4 – Design & Development

Louvreclad boast a highly experienced and qualified in-house research, design and drafting team. The team includes RPEQ registered structural and mechanical engineers and design drafters who have years of experience designing and detailing sunshades, louvres and screens for large developments within the commercial, education, government, health, industrial and public sectors.

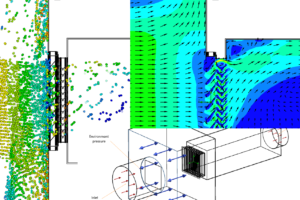

Our team are passionate about bespoke design and understand that innovation requires research and development. Whether you require calculations to confirm your louvre selection meets the air flow and rain defence requirements or you need structural support and detail advice for your next screen design, please get in touch with our team of experts to put your mind at ease.

At Louvreclad we are more than happy to work with you through this R&D process and will provide, sketches, calculations, and prototypes to support your design development.

-

- Structural Engineering & design support

- Project specific testing to Australian Standards

- Architectural finalisation

- Construction approvals

Stage 5 – Fabrication

Our local and in-house manufacturing capability combined with efficient storage facilities ensure short lead times and local industry participation.

Lean Manufacture and factory DIFOTIS (Delivered in full, on time in Specification) principles are a crucial part of Louvreclad’s project Management and quality is upheld with most metals processed, assembled and packaged under one roof.

-

- Schedule works

- Manufacturing of all components

- Powder coating

- Packaging

Stage 6 – Project Management & Installation

Louvreclad’s experienced team of project managers take the hassle out of project delivery, co-ordination & installation.

Louvreclad take the hassle out of installation and associated necessities such as site and transport logistics, by providing those services also. Including elevated work platforms, workplace health and safety, machinery hire and detailed contract administration.

Most Importantly, a Louvreclad installation minimises any risk and is backed by a comprehensive product and installation warranty bringing enduring confidence to your project.

-

- Site measure

- Logistics to site

- Cranage & access equipment

- Installation dates to builders requirements

Stage 7 – Completion & Certification

Louvreclad has robust processes in place which are documented to support each project and provide conforming solutions.

All projects are supported with relevant project specific design and engineering certification. Our commercial louvres and screen products, are designed, manufactured and installed in accordance with the superior quality and standards. These are all backed by ISO and AS certification.

-

- Practical completion handover

- Certification of works completed

- Warranties

- Operation & Maintenance manuals

What We Do

Our Commitment to Lean Innovation. RLC Business Consulting Director Roger Crothers, discusses the manufacturing methodologies utilised by Louvreclad and how implementing Lean processes streamlines the business and ensures you get it right first time.

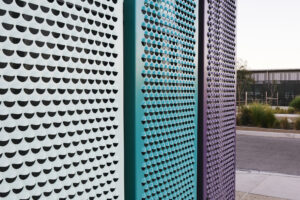

Louvreclad’s design and planning services will bring your concept to reality with our wide range of commercial louvres and screens that combine innovation with craftsmanship to deliver privacy, sun & weather protection, natural/smoke ventilation and distinct designs.

Value Engineering

Value Engineering = Smart Design

Louvreclad has the capability and capacity to value engineer the external louvres and sun shading solution for your project. Our experienced team can audit your façade concept to provide smart design solutions including pre-fabricated and modular construction options that meet the design intent and ensure the project is delivered on time and within budget.

Our flexibility, resources and product knowledge allow us to deliver solutions that seamlessly integrate with the external envelope of commercial buildings, with results that exceed all expectations.

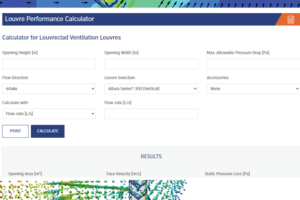

Louvre Performance Calculator

To use this calculator, input your data and select from drop-down menus to determine…

Architectural Window Hoods

Shading elements like sun hoods are often integral to the overall design aesthetic and therefore need to be fabricated from a system …

How CFD testing benefits louvre design

One of the advantages of CFD testing is it allows non-disruptive measurement to be carried out …

Custom Manufacturing

Our local and in-house manufacturing capability combined with efficient storage facilities ensure faster lead times…

Turn- key Solutions

We believe in making it easier at every touch point – from initial design and planning right through to installation or delivery.

What project design services does Louvreclad offer?

Louvreclad have a highly skilled design and project team who are available to assess your design and provide practical advice to ensure you select the right product for your project and you understand the detail and engineering requirements.

What are the benefits of value engineering?

Value engineering means smart design for efficient installation. Speed of construction is of increasing importance. Therefore, what can be worked out at the early design phase as far as constructability and economy of design goes, will speed up the whole project.

Why is early contractor involvement important?

If you get the design concept right at the start, it will prevent prevents hold ups and let the rest of the job flow smoothly.