A well-designed solar shading system improves internal conditions and contributes to a healthier and more comfortable working environment. Window Shrouds or Sun hoods provide a practical solution for horizontal and vertical window shading for commercial and multi-level high rise buildings.

Shading elements like commercial Aluminium Window Hoods and sun hoods are often integral to the overall design aesthetic and therefore need to be fabricated from a system with flexible and bespoke design capabilities.

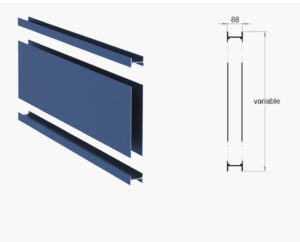

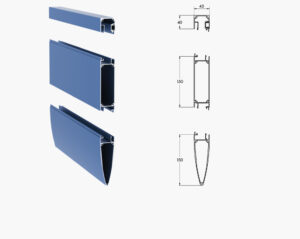

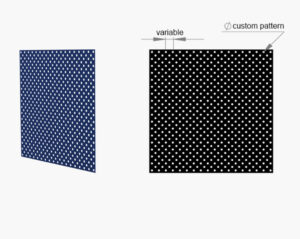

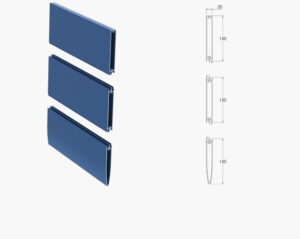

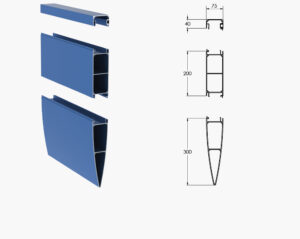

Louvreclad sun hoods can be designed, engineered and fabricated utilising a wide range of modular sun blades and custom fabricated sheet metal solutions, including Sheraton Series®, Caprice Series®, Scarborough Series®, Platinum and Polaris Series®

Products best suited to Window Hoods and Sun screens

Here is our selection of proprietary products that can be custom fabricated as window hoods to suit your project.

Architectural Window Shrouds

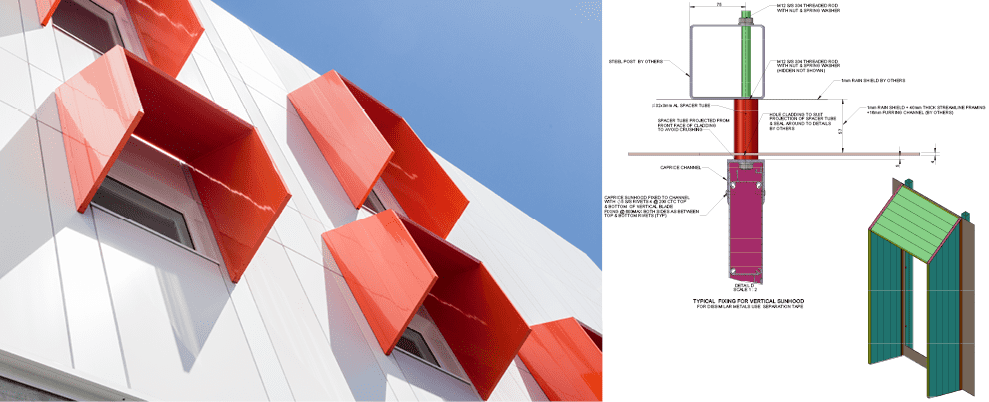

Managing the direct solar gains into a building to reduce overall heat loads can require a complex arrangement of vertical and horizontal shading elements. Therefore, every solar shading solution needs to respond to the unique requirements of each project. At Louvreclad we believe the best projects are a result of good collaboration between the architect, consultant and builder and we take pride in facilitating this collaboration to provide the best solution.

What are the key design requirements for integrating these into commercial facades?

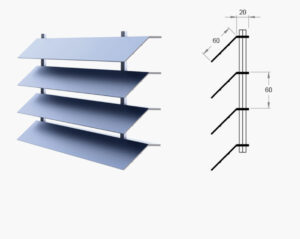

As every project is unique, Louvreclad sun hoods are a bespoke solution which are designed and engineered to suit the project. Maximum span is dependent on extrusion size selected and local wind pressures and a key design requirement for window hoods is to ensure sufficient structure is available for fixing. All of these modular and bespoke sun blades typically need to be fixed back to a structural substrate that has been designed to take their horizonal and vertical loads. Should you require any project specific design advice plea get in touch with the Louvreclad technical team today.

Privacy Screening with Window hoods

Aluminium Window hoods are often integrated with other privacy and sunshades within the façade design.

Louvreclad are passionate about modular construction and prefabricated solutions and understand that poor planning is a recipe for disaster – that is why we recommend getting in touch with our in-house design and engineering team who will take the time to focus on each detail. Through sketches, technical drawings and prototypes, our expert team takes the pressure off you and delivers the high-end result you are looking for.

Louvreclad are also committed to providing value to your project. By offering value engineering solutions – for example; a less complex design, a lighter weight product or a more practical prefab option you will achieve faster installation, on-site efficiencies, and overall reduction in build cost. By utilizing our in-house design and engineering team, we can ensure your project will be a success.

Modular powder coated aluminium sunhoods – Selected fixing system can significantly impact the final design aesthetic.

-

-

-

- For stud wall – Timber LVL or Structural Steel is required behind cladding

- Fins typically cannot be fixed directly to window joinery

- For face fixing we can use a H of F bracket, however the depth of the fin approx. max 400mm (Depending on local wind pressures)

-

-